Sabemos que la simplicidad de los procesos quirúrgicos muchas veces depende plenamente de las herramientas que se utilizan, por este motivo, te presentamos las mejoras que hemos realizado en nuestras fresas quirúrgicas y los topes de fresa: Para que tus cirugías sean mucho más rápidas y seguras, optimizando el flujo de trabajo.

Fresas quirúrgicas

La novedad principal es que se emplea el mismo diseño de fresa estándar, añadiendo una parte conectora y centradora para albergar el tope de fresa, lo que se traduce en un incremento de la longitud total – respecto a la fresa estándar – de un 10% máximo.

Características principales

· Codificación por color de acuerdo con el diámetro de implante, así como, el número de anillos:

– 1x anillo; secuencia de fresado estándar indicada para hueso tipo III-IV.

– 2x anillos; secuencia de fresado complementaria a la estándar indicada para hueso tipo I-II.

· Marcas láser de profundidad de perforación en la zona de corte, y marcado láser del diámetro, longitud, y el número de lote, en el vástago de esta.

· Reutilizables y esterilizables en autoclave. Se recomienda seguir el protocolo de limpieza y esterilización indicadas en las instrucciones de uso del producto.

Topes de fresa

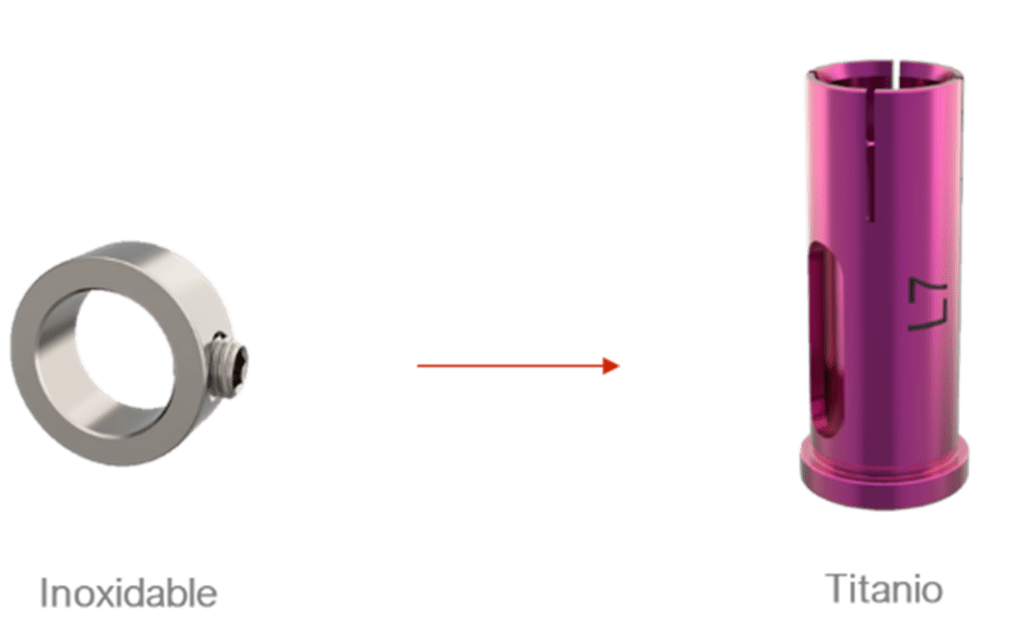

La novedad principal es que se modifica completamente el diseño; es decir, se sustituye el anillo de acero inoxidable quirúrgico con tornillo prisionero por un casquillo de titanio -grado médico 23 – anodizado de color, de acuerdo con el código de colores AVINENT® identificativo de los diámetros de implantes.

El nuevo sistema de topes de fresa para cirugía tradicional aporta un mayor control de la profundidad durante la osteotomía y seguridad del paciente

El nuevo diseño presenta:

· Aperturas longitudinales o ventanas para facilitar la evacuación de la viruta ósea, que se genera durante la osteotomía, así como, favorecer la irrigación.

· Valona o base cilíndrica en la parte inferior para favorecer el montaje con la fresa quirúrgica, así como su desmontaje o extracción.

Características principales

· Mayor control y simplicidad en la colocación.

· Codificación por color de acuerdo con el diámetro de implante y sus correspondientes fresas quirúrgicas para una fácil y rápida identificación.

· Marcado láser de la profundidad de perforación y número de lote.

· Reutilizables y esterilizables en autoclave. Se recomienda seguir el protocolo de limpieza y esterilización indicadas en las instrucciones de uso del producto.

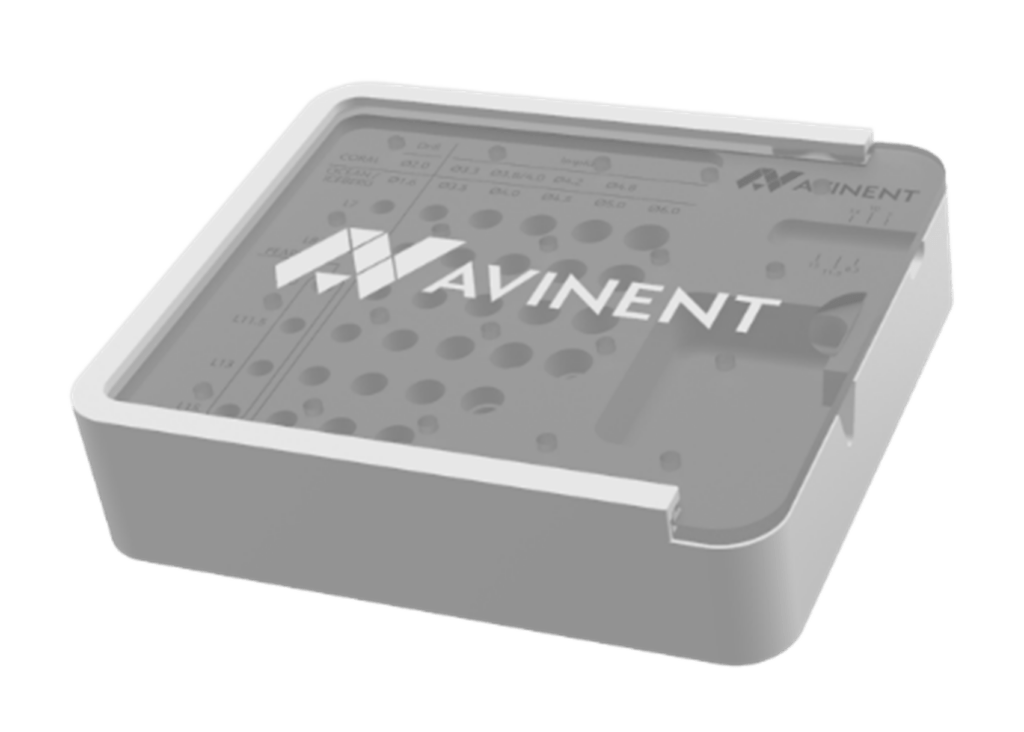

Caja de topes de fresa

La novedad principal es el nuevo diseño de caja de topes de fresa compuesta por una base (color blanco) y una tapa/cubierta (color gris transparente) con deslizamiento lateral.

Características principales

· Diseño compacto, ergonómico y estético.

· Dimensiones: 120 mm x 104 mm x 30 mm.

· Alojamientos individuales y específicos para cada tope de fresa, lo que permite la inserción sin contacto (no-touch) de estos directamente sobre la fresa quirúrgica.

· Marcados láser como guía para la correcta organización de los topes y orientación durante su uso.

· Mayor control y fiabilidad mediante el medidor de profundidad integrado en la propia caja para verificar la profundidad de perforación, una vez realizado el montaje entre la fresa y el tope.

· Extractor en forma de V integrado en la propia caja para todos los diámetros de topes de fresa.

· Bandeja/recipiente (30 mm x 40 mm x 11,5 mm) integrada/o en la propia caja para depositar los topes utilizados.

· Fácil limpieza y esterilizable en autoclave. Se recomienda seguir el protocolo de limpieza y esterilización indicadas en las instrucciones de uso del producto.

Para obtener más información y poder probar estas mejoras de primera mano, no dudes en ponerte en contacto con tu delegado comercial habitual.